Minerals that built America include hematite, magnetite, native copper, chalcopyrite, chalcocite, galena, and sphalerite—specimens prized by collectors for their distinctive crystal forms, colors, availability and affordability. But beyond their collectibility, these seven minerals played pivotal roles in transforming the United States from a patchwork of former colonies into a major industrial power.

These minerals were the primary sources of iron, copper, lead, and zinc, the metals that built the infrastructure for public works, transportation, manufacturing and defense. During the nation-building era from the mid-1800s to the early 1900s, access to large deposits of these seven minerals was critical to industrial growth.

During its first 60 years of independence, the United States imported most of its metals. The development of the first substantial domestic sources of metals in the 1850s was a turning point in the nation’s history. The ready availability of iron and copper opened the door to rapid industrial growth and provided exportable commodities to alleviate a negative balance in foreign trade.

The Iron Ores That Forged a Nation

The minerals that had the greatest impact on national growth were hematite and magnetite, the iron oxides that are the primary ores of iron.

Hematite and Magnetite: America’s First Iron Sources

Hematite (Fe2O3 ), the most abundant and widely distributed iron mineral, consists of 69.94 percent iron, crystallizes in the trigonal system, and has a high specific gravity of 5.3.

As a self-colored mineral, hematite’s color is caused by iron and the nature of its crystal structure. All earthy, massive, granular and particulate forms of hematite have a dull luster and reddish colors, but its macrocrystalline and botryoidal forms are gray-black, with crystal faces and botryoidal surfaces showing a bright, submetallic luster. All forms of hematite have a red streak.

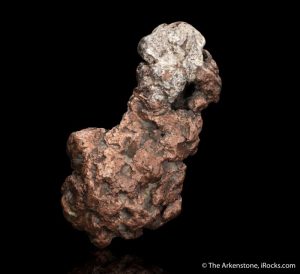

Magnetite (Fe3O4 ) has an iron-black color and a dull, metallic luster. It crystallizes in the isometric (cubic) system, usually as octahedrons with well-defined, triangular faces; most magnetite, however, occurs in disseminated and massive forms. Magnetite is a dense mineral that contains 72.3 percent iron and has a specific gravity similar to that of hematite.

Arkenstone, iRocks.com

Magnetite’s Magnetic Properties

A complex cationic composition makes magnetite the most magnetic of all minerals. Because iron is present as both ferrous (Fe2+) and ferric (Fe3+) ions, magnetite is correctly described as a ferroferric oxide. Within its closely packed crystal lattice, the ferric and ferrous ions are positioned at different lattice sites in an arrangement that permits a continuous flow of electrons between them. Always aligned in the same directional plane, this electron flow creates an electrical vector and a resulting magnetic field.

American Colonies and Mined Iron

American colonists first mined iron in the early 1600s from small deposits of hematite and magnetite. Local forges and furnaces soon began producing pig iron, and by the time of the American Revolution, the colonies had built a sizeable iron mining and iron smelting industry.

Another important colonial ore was bog iron, a mixture of goethite [FeO(OH)] and other iron oxyhydroxides, and lesser amounts of hematite and magnetite. Bog iron forms when iron-rich water collects in acidic, oxygen-deficient, bog-type wetlands. Chemical and biochemical processes then oxidize the dissolved iron, which precipitates in shallow layers as pea-size nodules of hydroxides and oxides.

During the early 1800s, the collective output of numerous small mines provided an ample supply of iron. By the 1850s, skyrocketing demand for iron and steel had exceeded supply.

Lake Superior Iron Ranges: Fueling the Industrial Boom

Just when needed, large deposits of iron ore were found in the Lake Superior region in Minnesota, Michigan and Wisconsin. These “iron ranges” were unlike any previously discovered iron deposits. They were linear, sedimentary formations 40 or more miles in length, in which reddish strata of shale and chert alternated with silvery-black layers of hematite and magnetite.

These deposits originated in the Precambrian Era when acidic seas were rich in dissolved iron. During the Great Oxygenation Event, some 2.4 billion years ago, the appearance of huge numbers of photosynthetic cyanobacteria began producing oxygen that reduced this acidity and precipitated layers of iron oxides in the sea-bottom sediments. Now called “banded-iron” ores, these lithified sediments are the earth’s oldest metal ores.

For the first 100 years of mining, the Lake Superior iron ranges yielded ores rich enough to smelt without concentration. Inexpensive water transportation was available to ship the ores to coal-rich areas on the lower Great Lakes that became centers for the production of iron and steel.

In 1850, the nation had produced only 100,000 tons of iron. But by 1900, thanks to the voluminous output of the Lake Superior iron ranges, it was turning out 25 million tons of iron per year – half the world’s production and more than enough to satisfy the huge demand for iron and steel. The Lake Superior iron ranges are still producing today, and have provided more than 4 billion tons of ore.

Red Mountain Hematite: A Southern Steel Catalyst

Another notable source of iron was the hematite ore of the Red Mountain district near Birmingham, Alabama. This red fossil ore, occurring in a 15-mile-long, 250-foot thick deposit, originated during the Silurian Period 420 million years ago when oxidized iron precipitated onto sea-bottom beds of fragmented crinoids, brachiopods and bryozoans. With its high lime content, red fossil ore was “self-fluxing,” meaning it could be smelted without a limestone flux. Mining began in 1860 to provide iron for the Confederacy during the Civil War. When mining ended a century later, the Red Mountain deposit had yielded 400 million tons of ore.

Arkenstone, iRocks.com

Copper Deposits That Powered American Progress

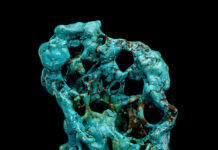

Like iron, copper was vital to industrialization. During the colonial period, Connecticut, Virginia, and New Jersey provided small amounts of copper from shallow deposits of malachite and cuprite. The metal was used for coinage, protective sheathing on the wooden hulls of ships and as the main component of bronze and brass alloys. The United States imported copper until the 1840s, when geological reports of an abundance of native copper on Upper Michigan’s Keweenaw Peninsula attracted hordes of miners.

Native copper exhibits a greenish-black, oxidized patina; fresh fracture surfaces are reddish, with a bright, metallic luster. At Mohs scale of hardness 2.5 to 3.0, native copper is slightly harder than gold and silver. With a specific gravity of 8.9, it is a bit denser than iron.

Native copper is never pure but contains varying amounts of arsenic, antimony, bismuth, iron, lead or silver.

Keweenaw Peninsula: The World’s Native Copper Capital

Geologists trace the origin of the Keweenaw native copper deposits to massive eruptions of basaltic lava roughly one billion years ago. The basalt contained large amounts of iron, smaller amounts of copper, and traces of silver. Because of degassing (emitting of sulfurous gases) during the eruptions, it was notably deficient in sulfur. Hydrothermal fluids later dissolved and concentrated much of the copper. Eventually, the more chemically active iron in the basalt displaced the copper from solution. Because of the basalt’s sulfur deficiency, most copper precipitated as native metal in vein and conglomerate deposits that were often of remarkable size.

These deposits were the largest native copper deposits ever discovered, and Keweenaw would be the only mining district in the world in which native copper was the primary ore. Three-quarters of the ore was native copper; the remainder was chalcocite (copper sulfide). Underground mines began production in 1844. Although initially inefficient, relying on hammers, hand steels and black powder, mining was profitable because the 99 percent pure native copper ore required no smelting.

Miners sometimes found masses of native copper weighing hundreds of tons each. By 1865, Keweenaw’s mines led the world in copper production and made the United States a major exporter of the metal. Keweenaw went on to produce 5.5 million tons of copper-most of it mined as a native metal. But by 1900, the Keweenaw mines alone could no longer keep pace with the booming demand for copper needed for national electrification.

Arkenstone, iRocks.com

Western Sulfides: Chalcopyrite and Chalcocite Emerge

In the 1870s, gold prospectors in Arizona, New Mexico, Utah, and Montana had discovered small, rich outcrops of azurite and malachite. By the 1890s, however, these direct-smelting ores, which contained roughly 50 percent copper, had been depleted. But miners also found massive, underlying deposits of chalcopyrite and chalcocite. Unfortunately, this sulfide mineralization, which graded less than two percent copper, was far too low-grade to be mined profitably with existing technologies.

Chalcopyrite, or copper iron sulfide (CuFeS2), consists roughly of equal amounts of copper, iron and sulfur. It crystallizes in the tetragonal system, usually as tetrahedrons, and occurs in massive and granular forms. Its brassy yellow-to-golden color and metallic luster often tarnishes, showing highlights of gold-purple iridescence. Chalcopyrite has a Mohs hardness of 3.5-4.0; its high copper-iron content gives it a relatively high specific gravity of 4.1-4.3.

Chalcocite, or copper sulfide (Cu2S), consists of nearly 80 percent copper. It crystallizes in the orthorhombic system as pseudohexagonal tabs and prisms with a dark gray-to-black color and a dull, metallic luster. It has a Mohs hardness of 2.5-3.0 and a high specific gravity of 5.8. Chalcocite originates both as a primary and a secondary mineral. It can be emplaced directly by copper-rich, hydrothermal solutions, or it can form when shallow, oxidized copper minerals are dissolved and redeposited at depth.

Western Copper: Chalcopyrite & Chalcocite

In the West, most chalcopyrite and chalcocite occur in massive, low-grade porphyry deposits. Geologically, the term “porphyry” refers to an igneous rock containing conspicuous crystals (phenocrysts) within a finer-grained groundmass. In its mining context, “copper-porphyry” refers to porphyry that has been secondarily enriched by copper mineralization, usually in the form of chalcopyrite and chalcocite.

Huge copper-porphyry deposits are located at Bingham Canyon, Utah, and Butte, Montana. Most, however, are in southern Arizona and adjacent New Mexico. All are “two-phase” deposits consisting of an upper oxidized deposit and a lower, much larger enriched porphyry deposit. Geologists refer to porphyry mineralization as “supergene enrichment” (literally “post-formation mineralization”).

Mass Mining and Flotation: Unlock Low-Grade Copper-Porphyry Deposits

These low-grade copper porphyry deposits had no value until the introduction of mass mining methods and the flotation separation process in the early 1900s.

Flotation separation concentrates the sulfide particles in low-grade, base metal ores.

Finely ground ore slurries are then mixed with hydrocarbon-based frothing agents in open tanks and vigorously agitated, while bottom aeration produces a continuously ascending column of bubbles. The sulfide particles adhere to the bubbles and form a froth that can be floated off as a metal-rich concentrate ready for smelting.

By 1910, using large-scale, open-pit, mass mining and flotation separation to exploit the West’s enormous, low-grade copper-porphyry deposits, the United States was turning out 600,000 tons of copper each year, amounting to 60 percent of world production.

Galena: The Backbone of America’s Lead Industry

Another mineral needed for industrialization was galena, or lead sulfide (PbS), the primary ore of lead. Consisting of 86.60 percent lead and crystallizing in the isometric system as well-defined cubes, galena has a Mohs hardness of 2.5 and a very high specific gravity of 7.4. It is dark gray, with a dull, metallic luster. Galena is emplaced by medium- and low-temperature hydrothermal solutions in vein-type deposits, and as massive replacement deposits in limestone. Galena is easily smelted at relatively low temperatures, with carbon from charcoal or coal serving both as a fuel and a reducing agent.

Mississippi Valley Lead: Early Colonial Resources

The nation’s first sources of lead were the “Mississippi Valley Type” carbonate-hosted, lead-zinc replacement deposits, named for their occurrences in Missouri, Iowa, Wisconsin and Tennessee. French prospectors discovered the richest of these deposits in southeastern Missouri in 1720. They initially mined outcrops of cerussite (lead carbonate, PbCO3) and anglesite (lead sulfate, PbSO4) to obtain lead for bullets, roofing sheets, sheathing for ship hulls, lead-tin alloys for movable printing type and solder.

The Rise of Galena Mining in Missouri and the Tri-State District

In the 1850s, American miners in southeastern Missouri began systematically mining the massive, underlying deposits of galena. Newly discovered galena deposits in the Tri-State Lead-Zinc District of southwestern Missouri and adjacent Oklahoma and Kansas added to the nation’s lead supply.

By the 1890s, demand for lead reached record levels. Along with its traditional uses, the metal was also needed for protective sheathing for electrical cables and, most importantly, anodes and cathodes in lead storage batteries. Large amounts of lead compounds served as pigments in white, yellow and red paints.

Argentiferous Galena: Silver and Lead from the West

A potential shortage of lead was averted when Western silver prospectors discovered large deposits of galena. Because of a chemical affinity between silver and lead, silver readily replaces lead in the galena crystal lattice. Unlike the galena from the Mississippi Valley Type and Tri-State deposits, much of the West’s galena is argentiferous, containing significant amounts of silver.

In the 1870s and ‘80s, silver prospectors in Colorado, Idaho and Arizona found rich deposits of argentiferous galena, notably in Colorado’s Leadville and Creede districts, and Idaho’s Coeur d’Alene district. These ores sometimes contained hundreds of troy ounces of silver per ton. Although many districts were well known for their prodigious silver output, they produced 25 to 30 times as much lead. In 1890, as one example, Leadville’s mines turned out 270 tons of silver along with 9,000 tons of lead.

Zinc: A Quiet Industrial Hero

Sphalerite (zinc sulfide, ZnS), the primary ore of zinc, also contributed to industrialization. Sphalerite, which contains 66.41 percent zinc, crystallizes in the isometric system, usually as tetrahedrons. With a specific gravity and Mohs hardness of 4.0, it occurs in hydrothermal veins and replacement deposits, often in association with galena, pyrite and chalcopyrite.

Zinc’s Early Role in Brass and Alloys

Standard base metal smelting processes are not amenable to zinc, which, with its low boiling point, is vaporized and lost. Early brass alloys were produced by adding sphalerite directly to copper-smelting mixes, enabling the zinc to combine directly with the copper. In the late 1800s, metallurgists finally devised special retorting and electrolysis processes to inexpensively recover metallic zinc, which opened the door to many new uses for the metal.

In addition to its traditional use in brass, zinc became needed as a metallurgical catalyst and as a component of many new specialty alloys, while zinc oxide served as a white paint pigment and an important chemical feedstock. Most zinc was used in galvanization. In galvanization protection, corrosive energies are expended on the more chemically reactive zinc coating, rather than the underlying steel and greatly extending the life of the steel.

Galvanization and Naval Use: Zinc’s Expanding Reach

Large amounts of zinc were also used as sacrificial galvanic anodes on steel-hulled ships. Large ships typically have several tons of zinc anodes bolted to the exterior of their hulls to protect against the rapid electrolytic corrosion of seawater. These zinc anodes need to be continually replaced as they corrode away. In the 1890s, just as the American navy and merchant marine were transitioning to steel-hulled ships, the countless tons of zinc anodes needed to protect their hulls were readily available.

In 1860, the nation’s zinc production was negligible, but by 1900 had topped 250,000 tons per year, more than half of world production. Almost all that zinc came from the sphalerite ores of the Mississippi Valley Type and Tri-State lead-zinc deposits and as a byproduct of Western silver-lead mining.

Minerals that Built America: Final Thoughts

Iron, copper, lead, and zinc were the metals that laid the foundation for America’s transformation into an industrial superpower. During the nation-building years, the United States was uniquely positioned to discover and develop exactly the right mineral resources, at exactly the right time. These are the minerals that built America. Today, when you admire specimens of hematite, magnetite, native copper, chalcopyrite, chalcocite, galena, and sphalerite, you’re not just holding a piece of geology—you’re holding a piece of American history.

This story about the minerals that built America appeared in Rock & Gem magazine. Click here to subscribe. Story and photos by Steve Voynick.