If you know how to drill holes in cabochons, creating decorative patterns is the next step. Here’s how to make a pattern with graduated size holes.

Getting Started

I started by selecting a slab with different colors with no definite pattern. It did have some internal clear distortions that were created during the formation of the material.

I went back to one of my favorite shapes – a curved teardrop – to design the piece. Past patterns of the cab had a gentle inside curve that fit my 8-inch diameter grinding and sanding wheels. This made grinding and sanding the curve easy to accomplish.

On this piece, I increased the inside curve and it mandated a different method to grind and sand the curve. I used a 1-inch Mizzy silicon carbide grinding wheel. These wheels are designed to be used dry. I like using them because I can access areas where bigger wheels will not reach. They grind rather quickly and aggressively and you do not have water obscuring your progress. Their use mandates wearing respiratory protection.

Smoothing the Surface

Mizzy wheels work quickly but do not leave a smooth surface. Considerable sanding efforts are needed to get a polishable surface.

I have changed from using silicon sanding paper to using silicon carbide sanding blocks. I start with the flat side of a 220-grit soft binder block. I hold the carving block parallel to the previously ground surface and push it at an oblique angle into the curvature. This allows the sanding to be quickly accomplished. I repeat this with 400 and 600-grit blocks to finish the sanding.

Locating the Holes to Cut

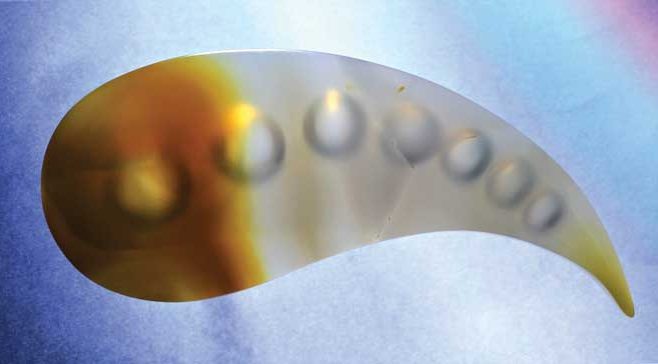

The height of the cab is 3 and 3/4 inches. I use a 3 and 1/4” diameter circle template to layout the location on the back of the cab for the diminishing-sized round holes. I space the largest holes further apart and reduce the distance between them as the holes get smaller.

The sets of diamond ball burs that I use are graduated in size from large to small. The sizes are not marked on each bur, so I have to measure each one with a caliper to ensure the ones I use are a consecutive amount smaller than the last one used.

Drilling the Holes

I drill the holes with a 36-grit bur to within 4mm from the front surface of the cab. I finish the grinding with a 220-grit bit and finally a 400-grit bit.

Polishing involves making small wood burs using a coarse file shaped to fit in the holes. You do not have to make a wood bur for each size of the hole. A smaller bit will polish a larger hole. I made four different sizes of bits including one small enough for the smallest hole. I use cerium oxide mixed with water to make a heavy paste to polish the holes.

When viewed from the front, the smaller holes at the top of the cab have a sideways oblong appearance because of the higher dome curvature of the cab at the curved point.

These bench tips about how to drill holes in cabochons previously appeared in Rock & Gem magazine. Click here to subscribe! Story by Bob Rush.