By Bob Rush

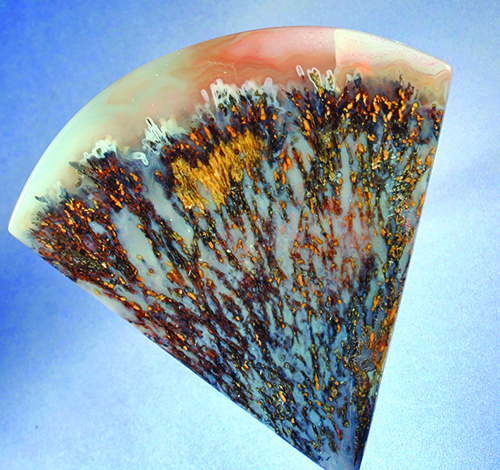

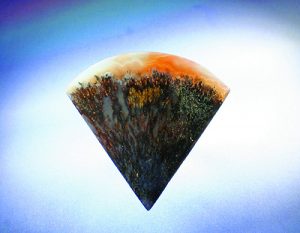

Ugh! We all have those moments when we see a fracture right in the center of the best pattern in the slab. A fracture is a crack in the material caused by stresses that were present during its formation, over perhaps millions of years since its formation, during the mining or extraction of the material, or by handling after it was mined. Fractures are serious defects that compromise the stone’s integrity.

If you hold the piece at an angle to a strong light, you can see the light reflect off the inner surfaces of the fracture. You can also detect the fracture by dragging your fingernail across the fracture line and feeling for the fracture edges.

Cracks Versus Crazing

“Crazing” is another type of fracturing that it is characterized by a weblike pattern of

multiple small fractures. It is often associated with some opal materials.

It is not unusual to have a “healed” fracture, one that was filled in by silica or other minerals that were deposited after the initial fracturing event. Healed fractures often reduce the risk of separation at the fracture line during cabbing, but they often distract from the desirability of the material because they still look like fractures. Healing often introduces minerals of other colors, making the fracture more evident.

Mostly, fractures are problems you need to work around while locating useful areas within the slab. At shows, dealers usually display their slabs in tubs of water to better show off their colors and patterns, but the water also conceals the fractures because it migrates into them.

Sealing Fractures

When examining these slabs, I wipe the surface with my inner arm or a paper towel. As the slab surface starts to dry out, the fractures become visible because they retain water. When the fracture is fully dry, you can hold the slab obliquely to a strong light and see the light reflect off the surfaces of the fracture.

You can treat the material with a fracture sealer and hardener called Opticon®. Fractures that reach the edge of the slab can usually be sealed, but if the fracture starts and ends within the material, it usually can’t. I do my fracture sealing after I have finished shaping and fully polishing the cab.

To fill the fracture, I cut one of the wells out of an aluminum muffin pan and shape it so that it holds the cab upright, resting on the edge that contains the fracture. I pour in enough of the resin sealer to cover the fracture, then place the muffin well and cab on a ceramic tile for heat protection. I swing a portable 100-watt incandescent lamp directly over the cab, positioning it as close to the cab as I can without touching it. The cab will heat up significantly within about an hour.

Sealing Steps

NOTE: Perform this procedure in a well-ventilated area and do not touch the heated cab with your fingers, because it will be very hot!

Place two pieces of small-diameter, flexible tubing on the tips of a pair of tweezers, and use the tool to pick up the hot cab. Carefully wipe the excess sealer from the cab with a paper towel. Hold the stone up to the lamp and look for any evidence of the fracture. None should be seen. Put the cab on a plastic tile spacer and mix a small amount of sealer with the hardener (10:1) on a piece of aluminum foil. Pick up the hot cab with the tweezers and apply a small line of the mixture directly over the seam where the fracture was, on the front, edge and back.

Put the cab on the tile spacer and move it back under the light. Leave it there for an hour, then turn the light off and wait a few hours for the sealer to harden. Remove the excess hardened sealer with a file. The fracture should not be visible after the treatment.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.