By Steve Voynick

Manganese is an element that we rarely, if ever, see in its metallic state, but that nevertheless plays a big part of our everyday lives. Manganese is present in everything from alloyed steels and aluminum beverage cans to clear glass, colored brick, and dry-cell batteries.

Elemental manganese and iron both have steel-gray colors and similar atomic weights. Manganese is much harder, however, and so brittle that it cannot be machined. It ranks 12th among the elements in crustal abundance. Because of its great affinity for oxygen, it does not occur on Earth in elemental form, but is sometimes found as a native metal in meteors.

Neolithic Art With Manganese

The most abundant manganese-bearing mineral is pyrolusite, or manganese dioxide (MnO2). Pyrolusite was used as a pigment in the black paints that Neolithic artists used to create Europe’s 17,000-year-old cave paintings. The exceptional hardness of the iron weapons of the ancient Greeks was due to the accidental incorporation of manganese into molten iron. The Romans later utilized pyrolusite in glass making, adding small quantities to decolorize glass and larger quantities to impart dark colors.

The name “pyrolusite” stems from the Greek words pyr (fire) and lousis (washing), and alludes to the mineral’s ability to remove color from molten glass.

By the mid-1700s, scientists began to suspect that pyrolusite contained a previously undiscovered element. In 1774, Swedish chemists Carl Scheele and Johann Gottlieb Gahn heated powdered pyrolusite with carbon to chemically reduce the compound and isolate a new metal that they named “manganese” (the Italian word for pyrolusite).

Growing Demand

In the 1880s, metallurgists alloyed manganese with iron to create the first high-quality, modern steels. The earlier carbon steels, while hard, were too brittle for many applications; manganese steels were much harder and far less brittle.

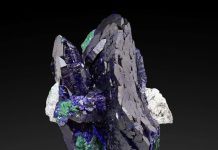

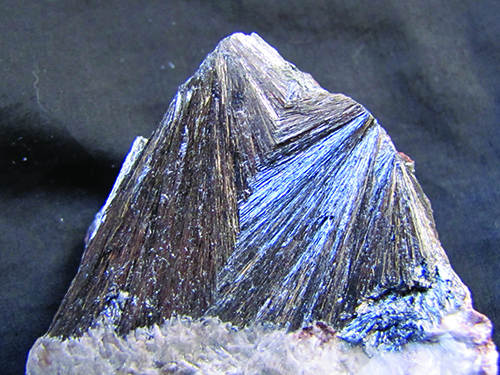

In the early 1900s, the growing industrial demand for manganese was satisfied by mining shallow deposits of pyrolusite. Pyrolusite, which crystallizes in the tetragonal system, usually occurs in massive forms or as radial aggregates of acicular crystals. It has a substantial Mohs hardness of 6.0-6.5, a specific gravity of 4.2, a steel-gray color, and a semimetallic luster that is sometimes accompanied by a bluish iridescence.

Because manganese has five common oxidation states (+2, +3, +4, +6, and +7), it forms numerous oxides, basic oxides, and hydrous oxides that include such minerals as manganite, manganosite, hausmannite, romanèchite and hollandite. These often occur together and can be very difficult to distinguish from pyrolusite. Such mixes of manganese oxides are known as “psilomelane”, or by the mining term “wad”.

Today, pyrolusite and braunite (manganese silicate) are the primary ores of manganese, about 18 million metric tons of which are mined each year. South Africa leads the world in manganese production, thanks to the huge Kalihari manganese fields, which are familiar to mineral collectors as a source of fine specimens of rhodochrosite (manganese carbonate).

Sources of Manganese

Other important manganese sources are China, Australia, Gabon and Brazil.

Although the United States is the leading manganese consumer, it has not mined manganese ores in 50 years and is completely dependent upon foreign supplies.

Ninety percent of all manganese is alloyed with steel. Because the atomic radii of iron and manganese are almost identical, manganese atoms can substitute for those of iron without distorting iron’s crystal lattice. While creating hard, non-brittle steel alloys, manganese also enhances iron’s ability to take on the desirable qualities of other alloying metals such as molybdenum, vanadium and chromium. Manganese also imparts corrosion resistance to the aluminum alloys used in beverage cans.

Pyrolusite serves as the electrolytic paste in dry-cell batteries and a decolorizing agent in glass manufacturing. Architectural brick contains various manganese compounds that, when fired, convert to manganese dioxide to produce a range of colors.

Many field mineral collectors have had first-hand experience with pyrolusite, but might not know it. In manganese-rich mineral deposits, it’s that omnipresent black powder that quickly stains skin and clothing.

Author: Steve Voynick

A science writer, mineral collector, and former hard rock miner, he is also the author of many references including, “Colorado Rock Hounding” and “New Mexico Rockhounding.”

A science writer, mineral collector, and former hard rock miner, he is also the author of many references including, “Colorado Rock Hounding” and “New Mexico Rockhounding.”