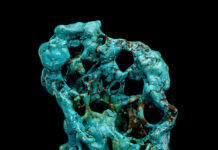

Thulite is a beautiful pink gemstone first discovered in 1820 in Norway on the island of Thule. It is a manganese-rich variety of the mineral zoisite, with inclusions giving it a unique coloring unlike other zoisite variations. It often resembles rhodonite or rhodochrosite but lacks the characteristic black streaks or banding. This translucent stone is not a jasper or rhyolite but stands out for its vibrant pink to deep rose and even purple colors. It’s usually joined with calcite and quartz, which can give it a speckled or veiny look.

Recently, miner Larry Odom, while out hunting for gold, came across a new find in the southwest region of the United States. This new find has a large variance in colors, with spots of galena throughout, giving it a metallic glittery addition to the pink material. Though this material can be found in several places on Earth, it’s still very scarce.

Thulite is an opaque material with a waxy luster and a Mohs hardness of around 6 to 6.5. Generally, it is very solid with very few, if any, fractures, giving almost all usable lapidary working areas with little to no waste.

How to Buy Quality Rough

When purchasing this material, it’s fairly easy to see what you are getting from the raw material by an outside visual inspection. The good news is that it will continue to cut with the same color range throughout each stone. If you are looking to get different color ranges, you will definitely need to buy several and cut each to see which you like best. It’s good to remember that once the complete cabochon is polished, it generally gives it a slightly darker color than the raw slab that you started cabbing.

Prepping Thulite Rough for Slabbing

Prepping Thulite Rough for Slabbing

When starting to slab your rough, examine your piece, and check to see if there are any cracks that might give way once you’re in the cutting process. This is where you might want to tap off the loose pieces with a rock hammer and hand-cut those at a later time.

When loading your saw, there really is no right or wrong direction in which to cut. However, I feel it’s best to read the direction of any fishers that might be showing in your rough piece and cut along the same direction with them. This ensures that once the slab is cut, it won’t split in half on you.

Step-by-Step Guide to Cabbing Thulite

The cabbing process is fairly easy. Although the material might be on the harder side, it cuts nicely and evenly, with no undercutting. Start on the 80-grit steel wheel to shape and dome your cabochon. You don’t have to do a lot of extra work on the 80-grit, as the 140 or 220 will quickly smooth it out. Once you are ready to start the 280-grit soft resin wheel stage, this is where you want to continue to dry the cab every so often and check for scratches. The 280 should easily remove any scratches, but be cautious, it will grind down quickly, still at this stage and possibly lose the height on your dome. Once you’re finished here, there should be no scratches left, and you can move on to the 600-grit wheel. By this time, you will see a lustrous gloss finish already starting to develop.

How to Polish Thulite for a Glossy Finish

Moving on to the 600-grit wheel and up to either the 3k or 8k grit, this is where you will most likely be finished. Thulite won’t usually get a mirror finish polish, so going up to a finer grit wheel most likely won’t give you any extra shine to your cabochon. Instead, I like to use cerium oxide on a leather buffing wheel, and softly give it a little polish without going too far and overheating the stone. Another method that works well is Zam polishing compound with a felt tip on a hand rotary tool.

This story about thulite previously appeared in Rock & Gem magazine. Click here to subscribe. Story sponsored by Russ Kaniuth.