Garnet’s industrial uses are one of the reasons garnet mining is booming. Garnet has become a bona fide industrial commodity because it is a nearly perfect industrial abrasive. In just the past 15 years, annual world mine production has quadrupled to 1.2 million metric tons of refined garnet concentrate worth $340 million dollars.

Abrasive Appeal

The word “garnet” refers to a group of complex silicate minerals with similar crystalline structures but diverse chemical compositions. Garnet’s general chemical formula is A3B2(SiO4)3, with “A” representing such divalent metallic ions as calcium, magnesium, ferrous iron, and manganese, and “B” representing trivalent ions like aluminum, chromium, ferric iron, and manganese. In certain rare garnets, the “B” cation can also include vanadium, titanium, or zirconium ions.

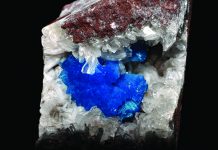

Many of the 14 garnet-group members form mutual solid-solution series. The most familiar and abundant of these garnet minerals are almandine, pyrope, spessartine, grossular, andradite and uvarovite. Garnet-group members vary widely in color, but only slightly in hardness, density, and index of refraction.

Garnet crystallizes in the cubic system, usually as dodecahedrons and trapezohedrons. Garnet’s Mohs hardness of 7.0-7.3 makes it somewhat harder than quartz (Mohs 7.0). With specific gravities ranging from 3.56-4.32, garnet is considerably denser than quartz (specific gravity 2.65).

Quartz sand has traditionally been the most widely used industrial abrasive because of its very low cost. But garnet, which offers many advantages that override its higher cost, is now displacing quartz sand in many abrasive applications.

Differences in Mineral Behavior

(Photo courtesy The Arkenstone/irocks.com)

Under the severe stresses of abrasive use, garnet and quartz behave quite differently. Both have a conchoidal fracture and no cleavage, but quartz’s tetrahedral atomic structure makes it the tougher and more durable mineral. Quartz breaks into rounded grains of the type found in the world’s dune fields and beaches. Garnet grains, however, do not become rounded; they break into sharp-edged bits that retain their abrading efficiency.

Quartz sandblasting agents can be used but once and cannot be recovered. But garnet mediums, with their significantly greater density, are easily recovered by inexpensive, hydraulic separation or “washing” methods. And because garnet grains retain their sharpness, they can be reused many times.

Garnet also has important health-related advantages. Quartz sandblasting agents create airborne dust of fine silica particles which, when inhaled, form silicic acid. Over time, silicic acid literally petrifies delicate lung tissues and greatly impairs pulmonary function. This debilitating industrial disease, called silicosis, can be fatal. Although garnet sandblasting agents also create airborne dust, it is non-toxic.

Garnet Applied Benefits

So while quartz-sand abrasive mediums cost less initially, garnet is cheaper in the long run for growing numbers of industrial applications.

The petroleum industry uses huge amounts of garnet sandblasting agents to clean compacted mud and silt from drill pipes and well casings. Garnet powder and grit is also used to polish optical lenses and metal, and as a media in filtration systems for water and industrial liquids. A rapidly growing use is as the abrasive agent in water-jet cutting, which eliminates the need for flame cutting in many manufacturing operations.

While quartz sand remains the leading industrial abrasive, demand for industrial-grade garnet continues to increase. Although garnet is relatively abundant with many occurrences, it has few major mine sources. Most garnet is mined from alluvial or beach deposits. China and India each account for one-third of world production. Australia is third at 15 percent.

The United States consumes 17 percent of world garnet production, but mines only three percent. In 2017, domestic garnet production amounted to 38,000 tons of refined garnet concentrate worth $11 million.

While garnet gemstones are also mined commercially, their quantity and value are minuscule compared with those of industrial-grade garnet.

This story about garnet industrial uses appeared in Rock & Gem magazine. Click here to subscribe. Story by Steve Voynick.