Smoky quartz carvers of all experience levels can benefit from learning new tools and techniques in a private stone carving workshop. Recently, award-winning gem carver Darryl Alexander, a multiple-time AGTA Spectrum Awards winner, offered a private workshop for Rock & Gem readers, giving lapidaries the chance to improve their skills and pick up expert tips along the way.

Smoky Quartz Workshop Setup

Darryl and his son Nick are the suppliers of the Mountain Mist diamond carving paste compounds, a favorite for many. This class was put together by Doug Malby and took place at Doug’s summer home in Chester, California. Doug facilitates communications among carvers and faceters and is involved with the University of Arizona’s Alfie Norville Gem and Mineral Museum.

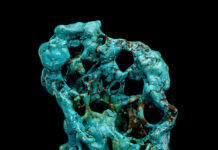

A table was set up in his driveway along with a tub of quartz crystals and scepters collected from the nearby Hallelujah Mine. A smoky quartz with a good shape was chosen for this workshop. Its termination had natural, undamaged frosted faces, but the sides were a little beat up.

A Diamond Pacific Pixie machine, a flex shaft machine, a 4-inch trim saw, and a Hi-Tech brand flat lap were also set up, along with the polishing compounds and wheels to be used with the flex shaft machine. Each grit and the wheels used with it were separately bagged to avoid cross-contamination.

Choosing the Right Crystal

The Hallelujah Mine produces smoky quartz and amethyst ranging from small, simply terminated crystals to massive scepters with huge, complex terminations. The base of the crystals is attached to the wall of the vugs they grew in, creating a crystal with a distinct, terminated top and a rough, broken bottom.

First, a Sharpie was used (since it does not soak into quartz as it does with softer stones) to mark where to cut off the rough bottom of the crystal. The 4-inch trim saw was used to make a cut, removing the raw bottom and creating a clean, flat bottom. Three of the six sides were chosen as the front of the carving, with the termination at the top.

Photo by Bruce McKay

Designing Your Carving

Darryl likes setting parameters such as final use and respect for the material, fluidity in design, and designs that work with the stone. “You can impose your will on the stone or you can adapt to the stone itself,” he says.

This carving was meant to showcase the Hallelujah Mine smoky quartz and would have a life as an example of intaglio carving, not a piece of jewelry. As a goldsmith, Darryl often cuts carvings for jewelry designs and must account for the physical locking of the gem into the gold or platinum and hold up to the rigors of daily wear. A stone for a ring can’t have easily broken parts that are exposed. Earrings can’t be too heavy. Pendants need a design that faces outward.

Photo by Bruce McKay

Smoky Quartz Shaping and Smoothing

The design was important aesthetically and to eliminate the irregularities in the crystal, yet still preserve a six-sided quartz crystal. First, with the Pixie and on the 80-grit wheel, the curves were cut up and down the crystal to get rid of the chips and maintain the six crystal faces. The front crystal face was taken to a polish first to effectively have a base polished surface. The natural surface of the termination was untouched.

Next, the Hi-Tech flat lap was used, moving through 325, 600, then 1200 grits to produce a flat surface that is impossible with the curved wheels of the cabbing machine. Darryl suggested using the area of the flat lap between seven and three o’clock on the face of the lap, using small sweeps. He said that large sweeps can cause rounding.

Photo by Bruce McKay

Protecting the Smoky Quartz Crystal from Damage

After polishing the first face, the other five crystal faces were cut to smooth, 1200-grit surfaces on the Pixie. The newly created curved surfaces took out the problems of the damaged crystal edges.

When mining at the Hallelujah Mine, they encourage you to use chopsticks or some similar soft tool to carefully remove crystals from the vugs they grow in, to avoid damaging them. To open up areas in the mine for digging, they use excavators to claw at the wall of the mine. This crystal probably had a run-in with the excavator rather than a chopstick.

The bottom was cut into a six-faced termination with each face matching up to the freshly shaped sides of the crystal.

Photo by Bruce McKay

Smoky Quartz Intaglio Techniques

The design consisted of curved grooves carved down into the back three crystal faces with hemisphere dimples cut around those. The back grooves and dimples would reflect through the front of the carving. We would have an intaglio carved crystal with the carving work reflected through the stone to the front.

After marking the V-cut curve designs on the front, the surface was cut with a coarse V-cut diamond wheel chucked into the flex shaft machine. To get these v-cuts to a polish, one must use V-cut wheels of the same shape as the original cut. These can be wooden V-cut wheels charged with diamond grits starting from coarse to polish, hard felt wheel V-cut wheels with various grits, or Diamond Pacific rubberized Nova diamond grit wheels. We went with Nova rubberized wheels, using coarse, medium, then fine, always used with water.

We then switched to hard felt wheels using the Mountain Mist 600-grit diamond paste without water. Just one side of the grooves was polished at a time, cutting both directions up and down each side to get an even surface. We started with low to medium speed going both directions on each face of the groove and then ramping up the speed to create an almost polished surface. To finish the polish, we used stiff-bristle brushes charged with 1200 and 2000-grit Mountain Mist polishing compound.

Photo by Bruce McKay

Detailing and Polishing

The next step was adding concave dimples into the surfaces using a round sintered diamond bur. Sintered burs have diamonds all through the steel bur end, while plated burs have diamonds attached to the surface of the bur through a plating process. Sintered materials are much better and more expensive. We used a 3mm sintered ball bur, starting with the side of the bur to start the hole. The holes were slowly ground to depth with very little chipping on the upper edge.

It is best if you have round polishing burs the same size as the diamond bur. These can be made from phenolic, wood, or hard felt and charged with diamond grit. Such burs are all available from carving supply shops. Without a round ball bur of the proper diameter to match the 3mm holes, Darryl suggested taking stiff-end bristle brushes and cutting the bristles short. The bristle brushes were charged with Mountain Mist Diamond paste, one brush for each grit, used without water, starting with 325 grit and then moving up through 600, 1200 and 2000 grit. This put a very nice polish on the dimples.

Each face was polished using the Pixie machine, cleaning up any rough edges on the top edges. Last, the six faces of the bottom termination were cleaned up and polished, getting rid of some minor chipping and doing the final aligning of the bottom termination faces with the six crystal faces.

This completed Hallelujah Mine smoky quartz carving, created under the tutelage of Darryl Alexander, is being donated to the University of Arizona Alfie Norville Gem and Mineral Museum in Tucson, Arizona.

Tools and Materials SuppliersAlexanders Jewelers

Rio Grande

Covington Engineering

Kingsley North

The Jade Carver

Lasco

SUVA Diamond Pacific

|

This story about making a smoky quartz intaglio previously appeared in Rock & Gem magazine. Click here to subscribe. Story by Bruce McKay.