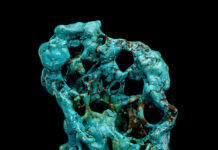

Agate doublet cabbing combines creativity with precision. In this project, I worked with a doublet incorporating an agate material capped with basanite.

Preparing and Assembling the Doublet

I started with a slab of Madison River blue agate that was 5mm thick, paired it with a 3.5mm basanite layer, and shaped it into a cabochon using a cab template. I ground them into the shape, then flattened them on a piece of glass with tumbling grit. I assembled them with Epoxy 330. I then drew a pattern on the basanite side with a brass scribe.

Carving Challenges and Adjustments

I began the agate doublet cabbing by carving with an 8.3mm diameter diamond wheel that was .86mm thick while following the sketched outline of the pattern. Because the lines had sharp inward curves, the carving wheel had to be of a small diameter. It soon became obvious that the axle on the small diameter wheel impinged on the surface of the carving before the wheel could reach through the basanite to the lighter backing piece. This was a major setback in the plan for the carving. It meant that the basanite layer must be made somewhat thinner for the carving’s success.

I decided to continue carving the pattern to the currently available depth so I wouldn’t have to retrace the carving pattern. Following this step, I went back to the grinding wheel and reduced the basanite thickness to 1.7mm. This allowed me to regrind the curving lines down to the white background layer.

Techniques for Detailing the Design

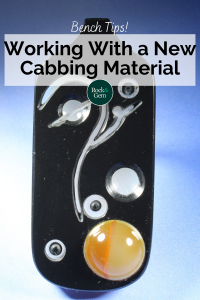

My next steps for the agate doublet cabbing involved using a small core drill to drill a circle down to the white layer. I did this in three locations. I used a 1-inch length of a 16dd nail to make a bit to grind the flat-topped center post to a round shape. I used a small metal bur to drill a hole into the nail piece. Using a tumbling grit, I shaped and sanded the end of the hole core to a rounded shape.

I used a round diamond ball bur to make two holes through the basanite. On the upper hole, I used an 11mm thin diamond wheel bur to grind a groove into the hole. This was to make it look like a planet with a thin halo.

Finishing the Agate Doublet Cabbing

Finally, I used a round diamond bur to grind down to the white layer. I then used an 11mm diamond wheel that was 2.5mm thick to make the hole for the seat of the agate hemisphere. I used my small steel cup wheel in my flat lap machine to make the agate piece. I used a piece of sculpture wax to hold the cab while fitting it for the mounting hole. I used Cratex wheels to sand the curved lines and a wood wheel bur to polish the carved lines.

I was quite pleased with the piece. The pattern was also visible from the back.

|

This article about agate doublet cabbing previously appeared in Rock & Gem magazine. Story by Bob Rush. Click here to subscribe.