By Bob Rush

Sometimes, when I am sorting through my slabs and trim saw cutoffs, I come across a particular piece that I know I want to make something with, but at that time I can’t picture exactly what.

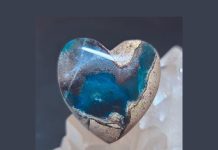

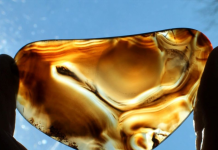

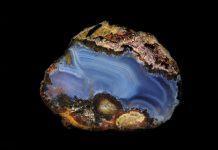

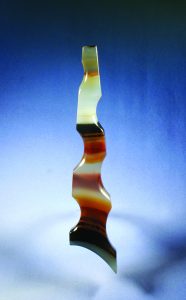

I have always been fascinated with necklaces that have a long, dangling centerpiece, so when I came across a piece of Brazilian agate that looked like it would work for a necklace centerpiece, I couldn’t resist using it. It was left over from a larger piece from which I had made a very large display cab. The cut-off piece was about 5 inches long and ¾ inch wide.

Challenging the Skill Set

I didn’t feel like just making a straight-sided, boring cab. I wanted to challenge my lapidary skills by utilizing more carving, especially with inside curves. I sketched some different ideas and finally settled on one that required carving semicircles in multiple sizes on the outside of the long sides of the cab.

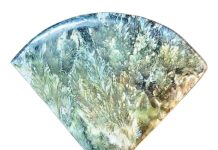

I began by shaping the general outline of the cab. Next, I used a small, circular template to draw circular segments of various sizes on each side of the preform. I’m calling the pattern “fanciful” because it is a rather uncommon shape for a cab.

I started by using the edge of my well-worn, 8-inch, 100 grit diamond wheel to remove as much of the interior of the circular segments as possible, then switched to 1-inch-diameter, heatless Mizzy silicon carbide grinding wheels. I use these a lot because they grind rather quickly and you don’t have to use water while grinding. This makes it easier to see your grinding progress.

Warning: They do generate considerable silica dust, so you must wear suitable respiratory protection, including a cartridge respiratory mask. A ventilation system is also recommended for abating the silica dust.

Working the Cab

After grinding the inner sides of the circular segments, I went to my lapidary machine and used an 8-inch expando wheel with a very well-worn 400 grit belt. I slid the belt edge over the side of the wheel to where it hung over by about ¼ inch. As you push the circular segment of the cab onto the overhanging edge, the belt will conform to the inside of the circular segment. Use a lot of water to keep the belt wet. This action will remove the grinding marks rather quickly.

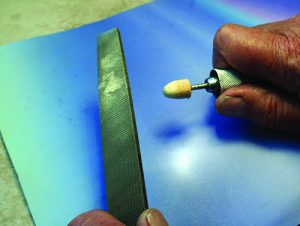

Use a small wooden wheel, made from a ½-inch dowel segment mounted on a screw-end mandrel, to sand the inner part of the circular segments with 600 grit tumbling grit and water. The end result of the sanding was a very smooth surface.

Focusing on Sanding and Polishing

Next, I sanded and polished the front, sides and back of the piece with my regular lapidary

equipment. Using another small, wooden wheel mounted on a screw-tip mandrel and Rapid Polish slurry, I polished the insides of the circular segments. Cerium oxide would work, as well. Admiring my handiwork completed the project.

Recently, our club, The Mother Lode Mineral Society, bought an ultrasonic drill for the Modesto Junior College lapidary classroom. I’ll use the machine to drill a small hole at the top of the piece so it can be strung on a necklace.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.